This research project within the Complexsurf laboratory focuses on studying the wetting behavior of liquid metals on solid substrates at an atomic scale using MD simulations.

In general, the wetting phenomenon is the process by which a liquid spreads over a solid surface and it plays a crucial role in various scientific and technological applications. The wetting behavior of liquid metals, in particular, has attracted significant attention due to their unique properties and potential applications in fields such as microfluidics, nanotechnology, and energy systems. To unravel the complex dynamics involved in liquid metal wetting, our group has turned to molecular dynamics simulation, a powerful computational tool that allows for detailed investigations at the atomic scale. This essay aims to explore the fascinating world of molecular dynamics simulation and its application in understanding the wetting of liquid metals.

Reactive wetting of Al-Ni:

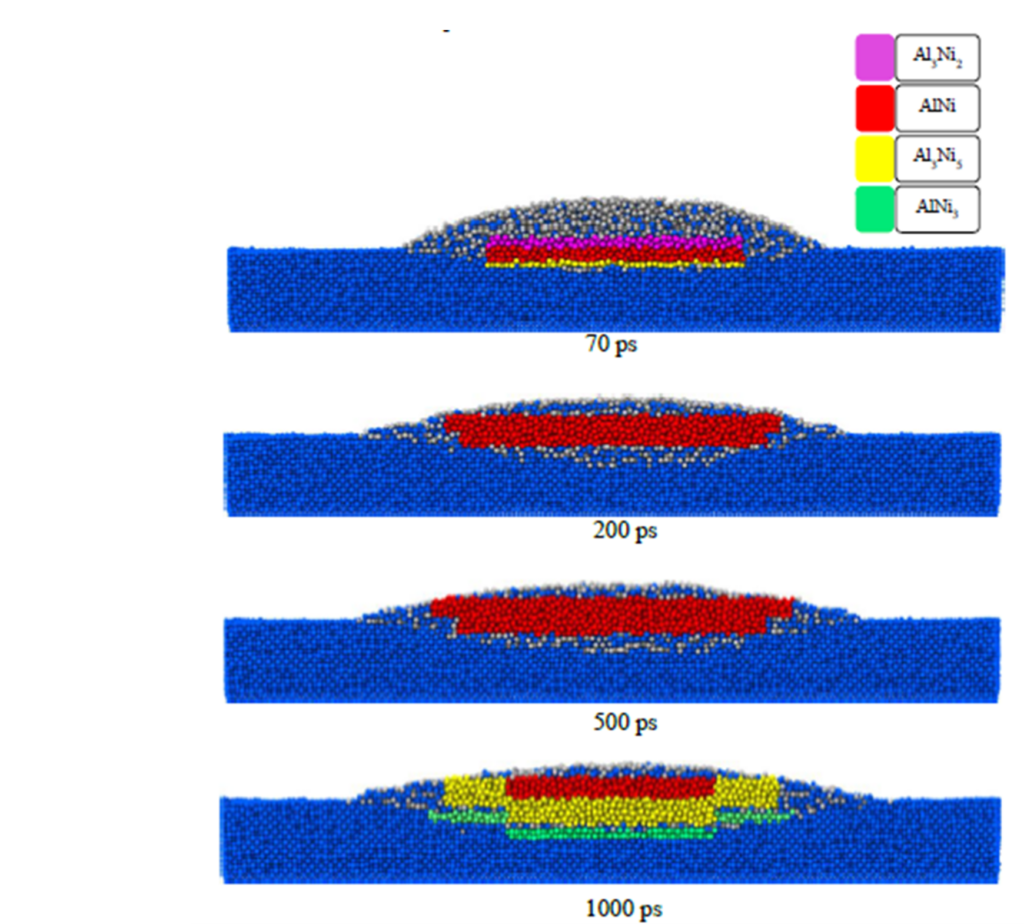

In this project, we mainly focus on the interactions of liquid Al on the solid Ni substrate and study the formation of intermetallics at high temperatures. The aim is to understand the evolution of intermetallics and its effects on the spreading of the liquid droplet. The analysis gives insight into understanding the dynamic reactions between Al and Ni and supports the wetting experiments performed in our group.

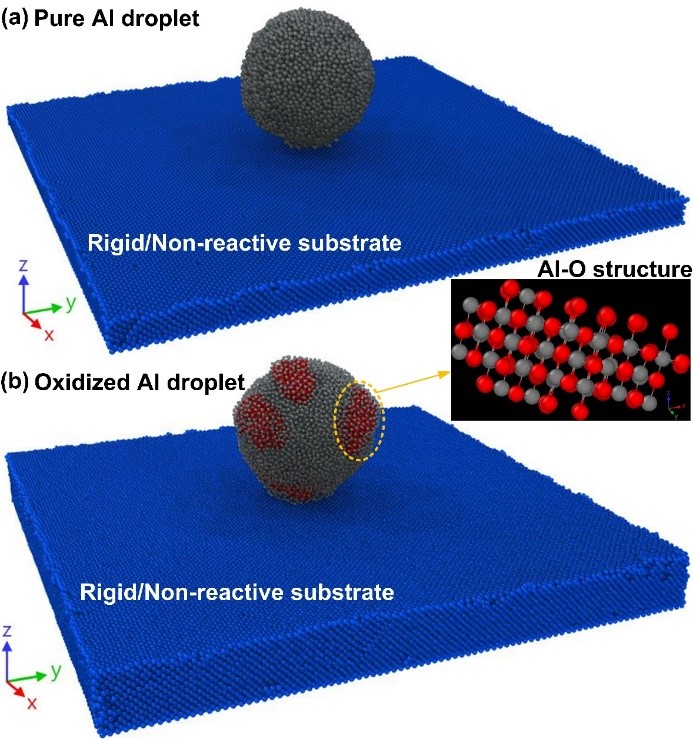

Effect of Oxygen on Al-Ni reactive wetting:

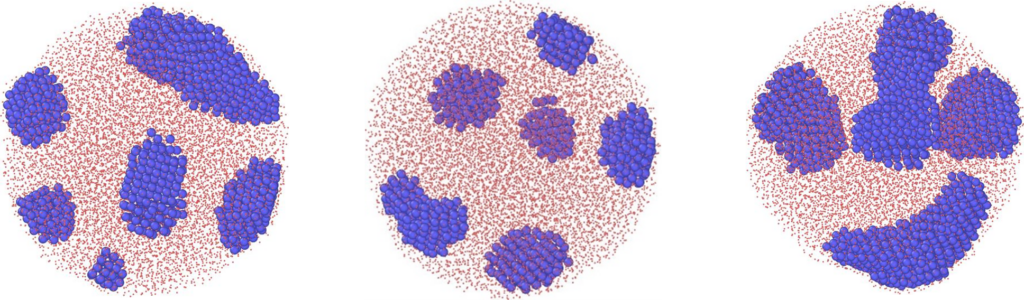

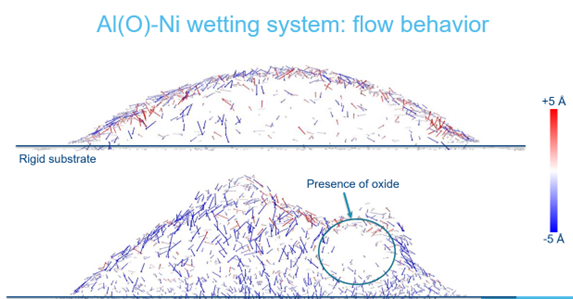

The reactive wetting between Al-Ni is strongly affected by the presence of oxygen and it disrupts the free flow of liquid Al. The presence of oxygen in the environment has a significant impact on reactive wetting phenomena through oxide layer formation, interfacial reactions, and changes in interfacial energy. Hence, it becomes really important to study the intrinsic behavior of the reaction between oxygen-Al and Ni. In this sub-project, we study the formation of oxides in the droplet, the effect of oxide concentration on the wetting behavior and the intermetallic formations.

Oxygen can alter the interfacial energy between the liquid metal and the solid substrate. The presence of oxygen at the interface can introduce additional interfacial energy contributions, such as oxide formation energy, which can affect the wetting behavior. Changes in interfacial energy can influence the contact angle, spreading dynamics, and stability of the wetting layer. Consequently, the wetting behavior of the liquid metal can be modified in the presence of oxygen, leading to variations in wetting kinetics and equilibrium wetting states.

Specifically, in reactive wetting, oxygen can also participate in chemical reactions with the liquid metal and the substrate material. These interfacial reactions can result in the formation of new compounds or phases at the interface, which may influence wetting behavior. The reaction kinetics, thermodynamics, and compatibility between the liquid metal, substrate, and oxygen govern the extent and nature of these interfacial reactions. They can either facilitate wetting or impede it, depending on the specific reaction products and their interaction with the wetting components.

Reactive wetting of other metals:

This project also explores the wetting behavior of different metallic systems such as Cu on Ni, and Al on Alumina. These MD simulations are well complimented with the experimental studies and help in understanding the wetting process- both reactive and non-reactive wetting better.