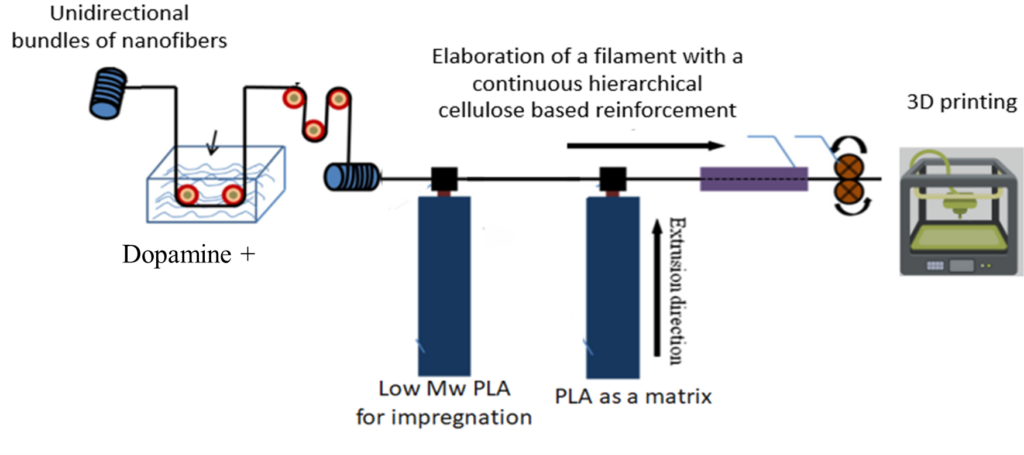

Natural fibre potential as reinforcement in composites is restricted by their inherent properties (e.g. moisture sorption) and variability (mechanical properties are different even for same species). Continuous reinforcing yarn is used in 3D printing, providing more strength and stiffness. For continuous natural fibre reinforced filaments, fibres must be twisted to keep the yarn integrity, reducing the mechanical properties of the composite due to fibre misalignment. BioCell3D proposes the incorporation of an aligned cellulose based reinforcement for continuous fibre 3D printing by creating our own technical natural fibre with hierarchical organization and enhanced physical properties. Continuous reinforcement will be obtained by electrospinning of cellulose derivatives as well as bacterial cellulose. The project aims to develop a “green” 3D printing additive technology for advanced structural applications, contributing to meet the regulatory requirements of recyclability.

Funding scheme: M-ERA.NET

Partners: Luxembourg Institute of Science and Technology, University of Maribor, Graz University of Technology

People involved: Ali Khodayari

Period: 2022-2025