Multi-scale wetting of fibers: principles, methods, and application examples

Characterizing the wetting properties of fibers is straightforward. First take a picture of a vertical fiber partially immersed in a liquid bath, water for example. Observing the shape of a liquid droplet engulfing a horizontal fiber is an interesting alternative. Second, draw a tangent to the liquid/vapour interface starting from the contact-line. The slope of that tangent gives the contact angle. Done.

How should this water contact angle be interpreted? Easy. A contact angle larger than 90° means hydrophobicity, lower means hydrophilicity. And surface chemistry together with surface topography, roughness in short, determine wetting properties.

Simple story….at least a first sight. There are still a many opened challenges.

First challenge: What is a static contact angle? Should it be measured at the nano-, meso-, or macroscale?

Second challenge: Which contact angle is most relevant? Static or dynamic contact angles? Receding or advancing? What about wetting hysteresis?

Third challenge: Are the fibers inert or reactive? Do they swell? Do the capillary forces induce surface modifications?

Fourth challenge: What are the mechanisms in action? Capillarity, rheology, inertia, evaporation, elasticity, solubilisation?

Fifth challenge: What about complex liquids? Nanofluids, mixtures, effect of surfactants?

Sixth challenge: What about fibrous materials, i.e. materials made of an assembly of thousands of straight or curly fibers?

Seventh challenge: What are the effects of temperature and relative humidity?

This list is actually almost endless.

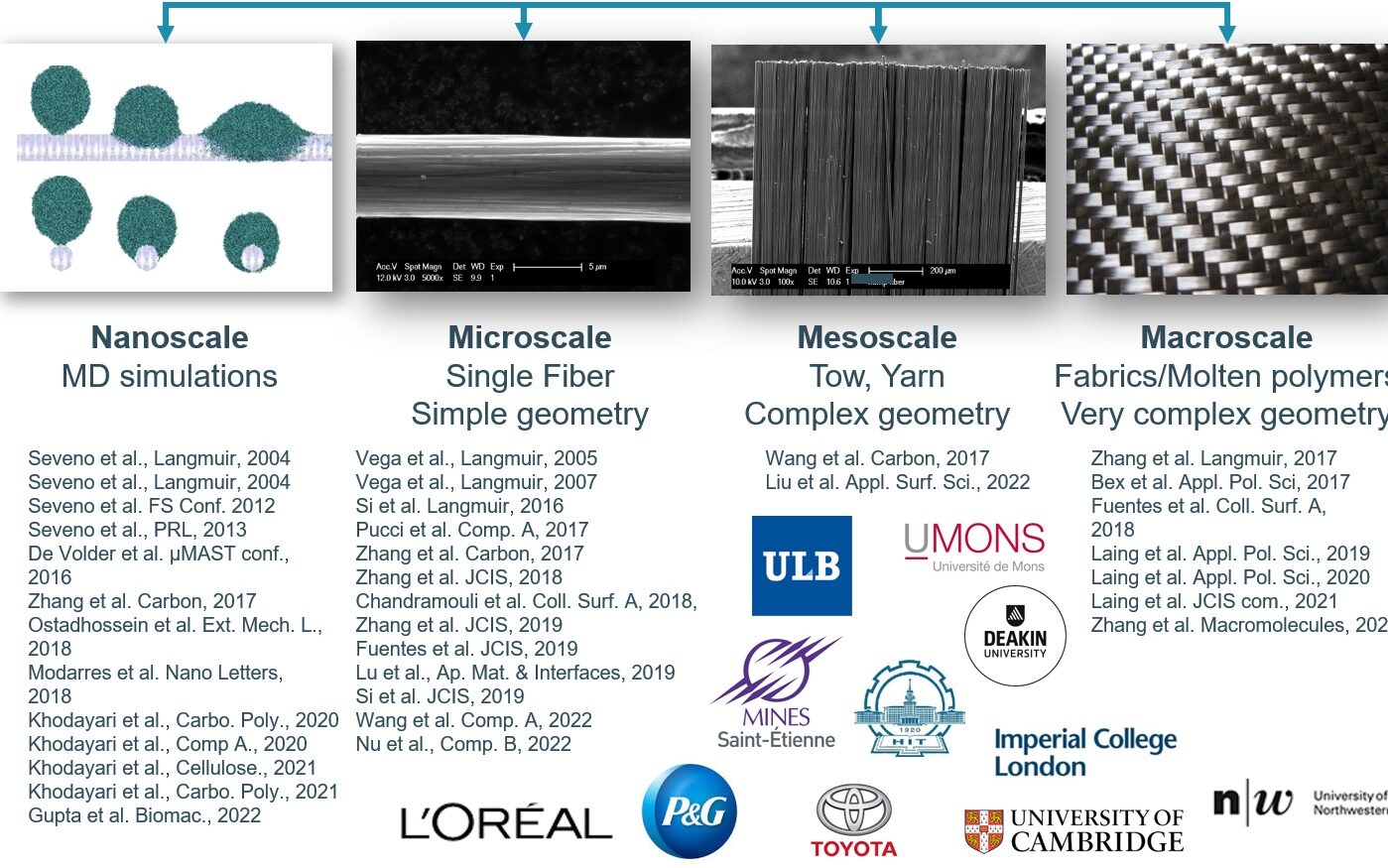

Let’s then consider some of these challenges and check how they can be tackled to finally better evaluate wetting properties. Indeed, even though fibrous materials are made of the same ubiquitous elementary brick, i.e. fibers, they can be found in various forms ranging, for example, from individual fibers (microscale), yarns/tows/strands (mesoscale), and fabrics (macroscale). Characterizing their surface properties through wettability then becomes tricky as the intrinsic physico-chemical surface properties must be considered together with the geometrical organization of the fibers. This project therefore aims at revisiting the wettability of fibers throughout scales.

Over the years, we made progress on how to accurately and reliably characterize the wetting properties of fibers as thin as carbon fibers and as complex as flax or hemp fibers. Our approach was to start from the monofilament (microscale) and to progressively move to yarns or tows (mesoscale) to finally reach the textile scale (macroscale). We did not only performed studies at every scale but were also able to link these scales together. The long-term goal focusing on predicting the wetting properties of textiles from the properties of its elementary constituents, the individual fibers.

We also study “nanofibers” like carbon nanotubes, TiO2 nanorods, or cellulose nanocrystals but this is another story….More info are available in the Modelling section.